|

|

|

|

|

|

METEOROLOGY INSTRUMENTS - The Thermometer

|

|

A thermometer is a device that measures the temperature of things. The name is made up of two smaller words: 'Thermo' (Greek 'Θερμό') means heat and 'meter' means to measure. You can use a thermometer to tell the temperature outside or inside your house, inside your oven, even the temperature of your body if you're sick. At the start of the seventeenth century there was no way to quantify heat. In Aristotelian matter theory, heat and cold were fundamental qualities. Like dry and wet, heat and cold were qualities combined with "prima materia" to make up the elements, earth, water, air, and fire. Thus earth was dry and cold, fire dry and hot, etc. Although one might speak of "degrees of heat or cold," there was no formal distinction between what we would call the extensive concept of heat and the intensive concept of temperature. Also these degrees were not measured, except perhaps in a very rough way as when a physician put his hand on a patient's forehead and diagnosed "fever heat". Measuring heat became a puzzle in the circle of practical and learned men in Venice to which Galileo belonged. The first solution was a thermoscope. Building on Pneumatics by Hero of Alexandria (1st century BCE), first published in the West in 1575, several authors had begun playing with the idea of the expansion of air as its heat increased, and vice versa. The first versions, usually called thermoscopes, were little more than toys. Benedetto Castelli wrote in 1638 about a device he had seen in Galileo's hands around 1603: "He took a small glass flask, about as large as a small hen's egg, with a neck about two spans long [perhaps 16 inches] and as fine as a wheat straw, and warmed the flask well in his hands, then turned its mouth upside down into the a vessel placed underneath, in which there was a little water. When he took away the heat of his hands from the flask, the water at once began to rise in the neck, and mounted to more than a span above the level of the water in the vessel. The same Sig. Galileo had then made use of this effect in order to construct an instrument for examining the degrees of heat and cold."

Over the next several years this thermoscope was developed by Santorio Santorio and Galileo's friend Gianfrancesco Sagredo (both in Venice), Galileo, and others to include a numerical scale. It had thus become a full-fledged air thermometer. The first series of quantitative meteorological observations date from this period. In other parts of Europe the inventor Cornelis Drebbel and Robert Fludd developed similar instruments. The questions about who was the first, and whether one derived his knowledge from another, are sterile ones which shed little light on the historical context in which this and other instruments (e.g., the telescope and barometer) developed. The near simultaneous (and surely independent) invention of the air thermometer illustrates the seventeenth-century trend toward quantification of natural phenomena--an essential dimension of the "mathematization of nature." The liquid in glass thermometer was developed in the 1630s, but a universal standard of temperature remained elusive. Each scientist had his own scale divisions, often based on different reference points. It is impossible for us accurately to convert their measurements to our temperature scale, and at the time it was impossible to compare temperatures in different places. In the early eighteenth century, universal temperature scales based on several fiduciary points (e.g. a mixture of ice and brine, a mixture of ice and water, body temperature, the boiling point of water) were developed by Daniel Gabriel Fahrenheit (1686-1736), Anders Celsius (1701-1744), and René-Antoine Ferchault de Réaumur (1683-1757). Of these, the first two are still in use, and the system of Celsius (extended to become an absolute scale in the nineteenth century) has become the standard scientific temperature scale. The thermometers we use today are different than the ones Galileo may have used. There is usually a bulb at the base of the thermometer with a long glass tube stretching out the top. Early thermometers used water, but because water freezes there was no way to measure temperatures less than the freezing point of water. So, alcohol, which freezes at temperature below the point where water freezes, was used. The red colored or silver line in the middle of the thermometer moves up and down depending on the temperature. |

|

|

|

|

|

To convert Fahrenheit temperatures into Celsius

|

|||

|

To convert Celsius temperatures into Fahrenheit

|

|||

|

Top of page

|

|

Anders Celsius (1701 - 1744) early became engaged in the general problem of weights and measures, including temperature measurements. Already

as a student he assisted the astronomy professor Erik Burman in meteorology observations. At that time there existed a large variety of thermometers with different scales. Perhaps

he already at this stage realized the necessity of a common international scale. A temperature scale must be based on one or two standard temperatures, called fixed points. For those it was natural to choose temperatures within the temperature domain

of practical interest, i.e. from about plus forty to minus twenty in modern Celsius degrees. Thermometers were simply used in meteorology, in horticulture, and sometimes for indoor

use. As fixed points one could use the human body temperature or temperatures of local origin such as the observatory cellar in Paris or the highest temperature in sunshine in

London. Of course also the freezing and boiling points of water were used, but it was not self-evident that they really were universal and e.g. independent of the geographic latitude. Anders Celsius should be recognized as the first to perform and publish careful experiments aiming at the definition of an international temperature scale on scientific grounds.

In his Swedish paper "Observations of two persistent degrees on a thermometer" he reports on experiments to check that the freezing point is independent of latitude (and also of atmospheric

pressure!). He determined the dependence of the boiling of water with atmospheric pressure (in excellent agreement with modern data). He further gave a rule for the determination of the

boiling point if the barometric pressure deviates from a certain standard pressure. The position of the degree zero on a temperature scale has created a lot of discussions. The French Réaumur scale had zero at the freezing

point but as regards other scales one placed zero outside the ordinary temperature region, thus avoiding the mixture of positive and negative numbers. The zero could be placed at a

low temperature, a method used by the Danish astronomer Ole Rømer and then adopted by Fahrenheit. Celsius was accustomed to

the Réaumur thermometer, but he also used a thermometer made by the French astronomer Joseph-Nicolas Delisle with zero at

the boiling point, thus creating a reversed scale with increasing numbers for decreasing temperatures, but avoiding negative numbers. This reversed scale was not as awkward as we think today and it served its purpose. The change to our modern direct scale was inevitable in the long run, however, but there

is no sense in trying to give the credit to any single person. Linné; has often been named as the inventor with reference to his famous work

"Hortus Cliffortianus" of 1737, five years before Celsius' publication. However, in studying Linné's work it is obvious that the few temperatures he mentiones

are impossible as modern Celsius' degrees. Linné met Fahrenheit in Holland and it is clear that he used Fahrenheit temperatures when he returned home to Sweden. Most probably Linné

abandoned the Fahrenheit scale when he learned about Celsius' research. After the death of Celsius in 1744 thermometers with a direct scale appeared in the meteorology reports under different

names, such as 'Celsius Novum', 'Ekström' and 'Strömer'. Linné had a great interest in thermometers, and he ordered a thermometer

with the modern scale from the instrument maker Daniel Ekström around 1744. The scale is mentioned in a dissertation by Samuel Naucler in

1745, but this does not indicate Linné as the single inventor of the modern scale. Certainly the change of scale became obvious to the Uppsala scientists in general. In an account of the

history of the thermometer in the Proceedings of the Royal Swedish Academy of Sciences 1749, Pehr Wargentin, Secretary of the Academy of Sciences,

mentiones Celsius, his successor Strömer and the instrument maker Ekström in connection with the direct scale. Linné is not mentioned at all. No single person can be given the credit. From the scientific point of view the most important contribution to the modern temperature scale is due to Celsius because of his careful experiments on the fixed points. The direction

of the scale comes in second place, and was hardly a great intellectual achievement. |

|

Top of page

|

|

The Fahrenheit scale, which measures temperature, was created by Daniel Gabriel Fahrenheit (1686-1736), a German-Dutch scientist,

in 1724. Fahrenheit, who devoted much of his life’s work to the measurement of temperature, also invented the alcohol and mercury thermometers. On the Fahrenheit scale, the point at which frozen water

melts is 32°, and the point where at which it boils is 212°. Between these two points is exactly 180°, a number easily divisible on a thermostat. Although we know with a degree of certainty what

measurements Fahrenheit used to determine his scale, his process of arriving at the final scale is largely unknown. Several stories have circulated regarding how Fahrenheit devised his scale. One is that he established 0° as the coldest temperature he could measure outdoors during the winter of 1708 to 1709

in Danzig, Germany. This measurement and Fahrenheit's own body temperature, which he measured at 100°, were the two marks on which he based the rest of his scale. Many think that either his thermometer was

off or he was running a fever that day, resulting in the relatively high reading on the bodily temperature. The scale was then divided into 12 separate segments, which were later divided into eight,

creating a scale of 96 separate degrees. In another story, Fahrenheit figured 0° by taking a measurement of the point at which equal parts of salt and ice mixed together melt. He then established 96° as the blood’s temperature.

Yet another story holds that Fahrenheit co-opted Ole Rømer’s scale of temperature. With this scale, 7.5° is the freezing point of water. Fahrenheit multiplied this number to get rid of the fractions,

and then refigured 32° as water’s freezing point, with 64 degrees separating the body’s temperature at 96°. He then marked degrees using six lines. Some believe that Fahrenheit was a Freemason, and because there are 32 degrees of enlightenment, he chose to use 32 as the melting temperature of water. Degrees are

also used as levels with the Freemasons, hence the use of the word on the scale. However, there is no documented evidence that Fahrenheit was a Freemason. In yet another story, it is said that Fahrenheit believed that a person would freeze to death at 0° and would die of heat stroke at 100°. This created a scale of 0° to 100° that encompassed the

range of livable temperatures. Another story states that Fahrenheit recorded the melting point of water, the boiling point and a human’s body temperature, and then put the melting and boiling points exactly

180 degrees apart. One far fetched story says that Fahrenheit observed the melting point of butter as 100° and set it accordingly. Because Fahrenheit degrees are 5/9 of a Celsius degree, it is easier to make more exact measurements without using fractions in the Fahrenheit scale. Fahrenheit continues to be used in the United

States, although most other countries that use the metric system changed to Celsius in the 1960s and 1970s. |

|

Top of page

|

|

The Kelvin temperature scale (K) was developed by British William Thomson, 1st Baron Kelvin (1824–1907) in the mid 1800s. The zero point on this scale is base on

the point at which the pressure of all dilute gases mathematically project to zero from the triple point of water. Recall that the triple point is the temperature at which liquid water, ice, and water vapor can

coexist simultaneously. The zero point of this scale is equivalent to -273.16 °C on the Celsius scale. This zero point is considered the lowest possible temperature of anything in the universe.

Therefore, the Kelvin scale is also known as the "absolute temperature scale". At the freezing point of water, the temperature of the Kelvin scale reads 273 K. At the boiling point of water, it reads 373 K. Lord Kelvin developed this scale with the help of a Carnot engine. The Carnot engine deals with the relationship between pressure, work, and temperature. The Carnot engine

is the most efficient engine possible. However, even it cannot reach 100% efficiency. If an engine was 100% efficient, no energy would be wasted. The Carnot engine is only theoretical, which means that all real

engines are even less efficient. |

|

Top of page

|

|

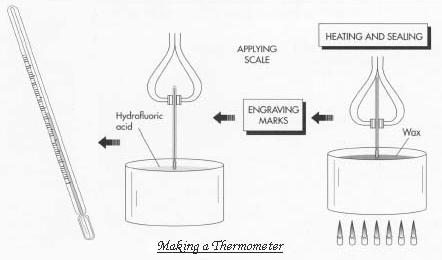

The operating principle of a thermometer is quite simple. A known measure of liquid (mercury, alcohol, or

a hydrocarbon-based fluid) is vacuum-sealed in a glass tube. The liquid expands or contracts when air is heated or

cooled. As the liquid level changes, a corresponding temperature scale can be read to indicate the current temperature. Thermometer manufacturers start with glass blanks with bores down the middle; these are usually received from glass manufacturers. The bulb

reservoir is formed by heating one end of the glass tube and pinching it closed. The bulb is sealed at its bottom, leaving an open tube at the top.

Thermometers consist of three basic elements: spirit-filled liquid, which responds to changes in heat and cold; a

glass tube to house the temperature-measuring liquid; and black ink to color in the engraved scale marks with legible

numbers. In addition, other elements are necessary for the manufacture of thermometers, including a wax solution used to engrave the scale marks on the glass tube; an engraving

engine that makes permanent gradations on the glass tube; and a hydrofluoric acid solution into which the glass tube is dipped to seal the engraving marks.

The Manufacturing Process

Although there are numerous types of thermometers, the production process for the most common of these—the classic household variety—is described below.

A. The glass bulb

B. Adding the fluid

C. Applying the scale

D. Quality Control The manufacturing process is controlled by widely adopted industry standards and specific in-house measures. Manufacturing design considerations include

quality control checks throughout the production process. The equipment used to perform fabrication tasks must also be carefully maintained,

especially with updated design protocol.

E. The Future Although the longstanding simple glass thermometer is unlikely to change, other thermometer.

|

|

Top of page

|

|

Recommended screen resolution: 1024x768, color quality: 32 bit and IE 5.x or higher Never base important decisions on this weather information Not to be used for protection of life and property!! KIFISSIA meteo Copyright © 2006 - Ioannis P. Fragos , All rights reserved

|